Optimizing Human-Machine Interface (HMI) Solutions for Textile Dyeing and Printing Machinery: A Cost-Benefit Analysis Report on BOE Displays and AMT Touch Technology (Presented by Hangzhou LEEHON Technology Co.,Ltd.)

Chapter 1: Optimizing Human-Machine Interface (HMI) Solutions for Modern Textile Dyeing and Printing Machinery

1.1. Introduction: Hangzhou LEEHON Technology Co.,Ltd. – Your Partner for Advanced Industrial Display Solutions

Hangzhou LEEHON Technology Co.,Ltd. (hereinafter referred to as "LEEHON Technology"), established in 2009, is a professional supplier of TFT LCD display panels and touchscreen solutions. The company possesses profound expertise in industrial applications, serving sectors including medical and automotive, and is dedicated to providing customized solutions to meet specific client needs.

LEEHON Technology has established close partnerships with numerous globally renowned display manufacturers, including BOE Technology Group (BOE), AU Optronics (AUO), Innolux Corporation (Innolux), Kyocera Corporation (Kyocera), Tianma Microelectronics (Tianma), and IVO Display (IVO). Notably, LEEHON Technology is one of the main agents for brands like BOE in mainland China. This extensive network and agency status enable LEEHON Technology not only to offer a diverse range of products but also to leverage its market insights and technical accumulation to recommend the most suitable display technologies and products for its clients.

This report aims to provide textile industry clients with a detailed HMI solution selection guide, focusing on specific BOE display models distributed by LEEHON Technology. These models, when paired with AMT resistive touchscreens, demonstrate superior cost-effectiveness compared to competitors. LEEHON Technology's "total display solutions," which include LCD screens, touchscreens, control boards, and cables, can significantly simplify the procurement process and integration work for textile machinery manufacturers, reducing development risks. This reflects its core value as a solutions provider. The company's long history and partnerships with multiple leading manufacturers ensure the objectivity and reliability of its recommended solutions.

1.2. The Critical Role of HMI in Textile Automation and Industry 4.0

As global manufacturing advances towards Industry 4.0, the textile machinery sector is undergoing profound changes. The proliferation of automation technology, aimed at improving production efficiency, ensuring product quality stability, and reducing operational costs, has become an inevitable trend in industry development. In this process, the Human-Machine Interface (HMI) plays a crucial role, serving as the core hub for interaction, control, and monitoring between operators and complex machine systems.

Modern HMIs are no longer just simple control panels; they are increasingly becoming key nodes for data-driven operations. In process-intensive industries like textile dyeing and printing, HMIs need to clearly and intuitively display a large amount of real-time production data, equipment status, process parameters, and diagnostic information, helping operators make quick and accurate judgments to optimize production processes. Fuji Electric, in its textile machinery retrofitting case, modernized equipment by replacing traditional manual buttons with HMIs, fully illustrating the role of HMIs in enhancing equipment sophistication.

The rise of smart manufacturing and the Industrial Internet of Things (IIoT) has further amplified the importance of HMIs. Market trends indicate that the growth in industrial display applications is closely related to the development of automation, Industry 4.0, and IoT technologies. In the textile industry, this means HMIs need to possess stronger data processing capabilities, network connectivity, and the potential to support remote monitoring and diagnostics. For textile enterprises facing challenges in efficiency improvement and complex production management , adopting advanced HMI technology is a key measure to maintain competitiveness.

1.3. Addressing Challenges: Key HMI Requirements in Dyeing and Printing Environments

Textile dyeing and printing workshops are known for their harsh production environments, which place extremely high demands on the durability and reliability of HMI systems. When selecting HMI solutions, the following key environmental factors and operational requirements must be fully considered:

- Temperature and Humidity: Dyeing workshops typically experience significant temperature fluctuations and high humidity levels. The dyeing process involves high-temperature water and steam, which can lead to elevated ambient temperatures around equipment. Concurrently, air humidity is also high, easily affecting conventional electronic devices. HMIs need to operate stably within a wide temperature range, such as 0°C to 50°C or even broader industrial standards (e.g., -20°C to +70°C), and under relative humidity (RH) conditions of 40-60% or higher.

- Dust and Particulates: The production process inevitably generates suspended particles like lint and fiber dust, which can infiltrate equipment interiors, affecting the HMI's normal operation and lifespan.

- Liquid Ingress and IP Protection Level: HMI devices may be directly exposed to water splashes, steam, condensation, and corrosive dye or chemical mists. Therefore, HMI enclosures need an adequate protection level, such as IP54 (dust and splash-proof) or IP65 (completely dust-proof and water-jet proof), to ensure the safety of internal electronic components.

- Chemical Corrosivity: The dyeing process uses various dyes, auxiliaries, acids, alkalis, and cleaning agents. The HMI front panel, especially the touchscreen surface, must be able to resist corrosion from these chemicals to avoid discoloration, blistering, material dissolution, or performance degradation.

- Vibration: Textile machinery (especially large dyeing and printing equipment) generates continuous mechanical vibrations during operation. The HMI structure must be robust and capable of withstanding a certain level of vibration (e.g., meeting a 1.5G vibration test standard) to ensure the stability of internal connections and the clarity of the display.

- Visibility and Clarity: Lighting conditions in workshops vary. HMI screens need sufficient brightness, high contrast, and good color performance to ensure information remains clearly readable under different lighting conditions. Anti-glare (AG) surface treatment is also very important for reducing reflections and enhancing the visual experience.

- Glove Operation: For safety and hygiene reasons, operators often need to wear gloves. Therefore, the HMI's touchscreen technology must support reliable glove operation. Resistive touchscreens, due to their pressure-sensing principle, are generally well-compatible with various types of glove operations.

Overall, the textile dyeing and printing environment presents multi-dimensional challenges to HMI robustness. No single superior performance feature can meet the demand; instead, a comprehensive consideration of its overall ability to withstand high temperature and humidity, dust and water, chemical corrosion, and vibration is required. In such environments, resistive touchscreens often have an advantage over capacitive touchscreens due to their insensitivity to surface contaminants (like water stains, minor oil smudges) and reliable glove operation characteristics. Simultaneously, the chemical compatibility of HMI enclosure and touchscreen surface materials directly relates to the device's service life and total cost of ownership (TCO) in corrosive environments.

Table 1: Key HMI Requirements Checklist for Textile Dyeing and Printing Environments

| Requirement | Target Specification/Level | Importance for the Textile Industry |

|---|---|---|

| Operating Temperature | -20°C to +70°C or wider | Adapts to temperature changes in the workshop caused by equipment heat dissipation and process heating |

| Storage Temperature | -30°C to +80°C or wider | Ensures weather resistance of the equipment when not in operation |

| Relative Humidity | Operable up to 90% RH (non-condensing) | Copes with the generally high humidity environment in dyeing workshops |

| IP Protection Level | At least IP54, IP65 recommended for wet areas | Prevents ingress of dust, water splashes, water jets, etc., protecting internal electronic components |

| Chemical Corrosivity | Resistant to common dyes, auxiliaries, acid-base solutions, and cleaning agents | Avoids damage to HMI surface and functionality due to chemical contact, extending service life |

| Vibration Resistance | Withstands at least 1.5G (14.7 m/s²) of vibration | Ensures stable operation in a mechanical vibration environment, preventing loose connections or display abnormalities |

| Display Brightness | At least 300 cd/m², higher brightness and anti-glare treatment recommended | Guarantees information readability under different workshop lighting conditions |

| Touchscreen Technology | Supports gloved operation, insensitive to water droplets, stains (e.g., resistive) | Adapts to operators' habit of wearing gloves, ensures reliable input in environments with liquid splashes or dirt |

| Backlight Lifespan | Industrial grade standard, e.g., 30,000 hours or more | Reduces maintenance frequency, lowers downtime risk and replacement costs due to backlight failure |

| Electromagnetic Compatibility (EMC) | Conforms to relevant industrial standards | Ensures stable HMI operation in complex electromagnetic environments, unaffected by and not interfering with other devices |

| Power Supply Voltage | Adapts to industrial standard power supply | Easy to integrate into existing equipment control systems |

| Interface Type | Provides common industrial interfaces (e.g., LVDS, USB, RS232) | Facilitates connection with PLCs and other control systems |

Through the above list, the stringent requirements of the textile dyeing and printing environment for HMIs can be clearly understood. The BOE display and AMT resistive touchscreen combination solutions recommended by LEEHON Technology are precisely selected and configured to address these challenges.

Chapter 2: BOE Display Solutions and AMT Resistive Touch Technology Tailored for the Textile Industry

This chapter will detail three BOE LCD display panels selected by LEEHON Technology for the textile industry, and their integrated solutions with AMT high-quality resistive touchscreens. These solutions are optimized for the harsh environmental requirements of the textile dyeing and printing industry mentioned earlier, aiming to provide a reliable, durable, and cost-effective human-machine interaction experience.

2.1. Solution Focus One: BOE BA104S01-300 (10.4-inch) with AMT9509 Resistive Touchscreen

BOE BA104S01-300 LCD Display Panel

The BOE BA104S01-300 is a 10.4-inch SVGA (800x600) resolution TFT-LCD display module. Its main specifications include a typical brightness of 350 cd/m², a contrast ratio of 800:1, an operating temperature range of -20°C to +70°C, and a WLED backlight lifespan of up to 30,000 hours. The panel uses an LVDS interface and has a 1.5G anti-vibration capability, ensuring stable operation in industrial environments. In terms of power consumption, the panel's logic circuit has a typical power consumption of about 0.5W, not exceeding 0.59W maximum; the backlight power consumption is typically 1.92W, with a maximum of 1.98W. Therefore, the maximum total power consumption of the entire module is approximately 2.57W, demonstrating good energy efficiency.

AMT9509 Resistive Touchscreen

The matching AMT9509 is a 10.4-inch (4:3 aspect ratio) 4-wire resistive touchscreen designed for industrial control systems. It features a light transmittance of no less than 80%, a surface hardness of 3H, can operate stably within a temperature range of -20°C to +70°C, and offers two common interfaces: USB and RS232. As an industrial-grade product, the AMT9509 is known for its high reliability, with the touch lifespan of its 4-wire resistive touchscreen typically exceeding one million actuations.

Combined Advantages and Textile Machinery Application

The combination of BOE BA104S01-300 and AMT9509 provides a balanced and cost-effective HMI solution for textile machinery. The 10.4-inch size is suitable for various control panel applications; the 350 cd/m² brightness and 800:1 contrast ratio are sufficient for most indoor industrial visual requirements; the wide operating temperature range can adapt to the actual working conditions of most factories. The addition of the AMT resistive touchscreen ensures reliable input when operators wear gloves or when the screen surface has minor contaminants (such as water droplets or dust). The panel's inherent 1.5G anti-vibration capability further enhances its applicability on mechanical equipment. LEEHON Technology recommends this model for industrial and medical fields, which also indirectly proves its maturity and reliability in practical applications.

The power consumption control of this combined solution is particularly outstanding, with a maximum total power consumption of about 2.57W. For textile workshops deploying a large number of HMI devices, the long-term cumulative energy-saving benefits are significant. This not only helps reduce operating costs but also aligns with the current manufacturing trend towards green energy conservation.

Table 2: Detailed Specifications – BOE BA104S01-300 & AMT9509 Resistive Touchscreen

| Parameter | BOE BA104S01-300 Specification | AMT9509 Specification |

|---|---|---|

| Size | 10.4 inch | 10.4 inch |

| Resolution | 800 x 600 (SVGA) | Adapts to 800 x 600 |

| Brightness | 350 cd/m² (Typ.) | - |

| Contrast Ratio | 800:1 (Typ.) | - |

| Viewing Angle (L/R/U/D) | 80/80/65/75 (CR≥10, Typ.) | - |

| Operating Temperature | -20 ~ 70°C | -20 ~ 70°C |

| Storage Temperature | -30 ~ 80°C | -40 ~ 80°C |

| Backlight Type/Lifespan | WLED / 30,000 hours (Min.) | - |

| Panel Logic Power Consumption | 0.50W (Typ.) / 0.59W (Max.) | - |

| Backlight Power Consumption | 1.92W (Typ.) / 1.98W (Max.) | - |

| Total Power Consumption | 2.57W (Max.) | - |

| Vibration Resistance (Panel) | 1.5G (14.7 m/s²) | - |

| Touch Type | - | 4-wire Resistive |

| Touch Interface | - | USB, RS232 |

| Transmittance | - | ≥80% |

| Surface Hardness | Anti-Glare (AG) | 3H |

| Touch Points/Lifespan | - | Single-point / >1 million actuations |

| Signal Interface (Panel) | LVDS (1 ch, 6/8-bit), 20 pins | - |

| Supply Voltage (Panel) | 3.3V (Typ.) | - |

This table clearly lists the core technical parameters of this 10.4-inch solution, providing a solid data foundation for technical evaluation and subsequent cost-benefit analysis.

2.2. Solution Focus Two: BOE BA121S01-200 (12.1-inch) with AMT9542 Resistive Touchscreen

BOE BA121S01-200 LCD Display Panel

The BOE BA121S01-200 is a 12.1-inch SVGA (800x600) resolution TFT-LCD display module. Its typical brightness is 400 cd/m² (some sources indicate 430 cd/m²), with a contrast ratio of 800:1, and an operating temperature range of -20°C to +70°C. This panel also uses WLED backlight with a lifespan of 30,000 hours and is equipped with an LVDS interface. Regarding power consumption, the panel's logic circuit has a typical power consumption of about 0.4W, maximum 0.45W; the backlight part consumes more, with literature recording PLED (LED backlight unit power consumption) as 6.0W or 6.12W. Therefore, its total power consumption is estimated to be between 6.4W and 6.57W.

AMT9542 Resistive Touchscreen

The AMT9542 is a 4-wire resistive touchscreen suitable for 12.1-inch (4:3 aspect ratio) displays. It features a light transmittance of no less than 80% and a surface hardness of 3H, with an operating temperature range also from -20°C to +70°C. It supports USB and RS232 interfaces and is designed for industrial control system applications, emphasizing high reliability.

Combined Advantages and Textile Machinery Application

Compared to the 10.4-inch solution, the combination of BOE BA121S01-200 and AMT9542 offers a larger display area. This is a significant improvement for complex HMI interfaces that need to display more data information or require a larger touch operation area (convenient for gloved operation). The 400 nits brightness is also slightly higher than the former, helping to improve readability under certain lighting conditions. This solution also inherits the reliability of AMT resistive touchscreens in harsh environments (such as humidity, dust) and when operated with gloves. LEEHON Technology applies this model to industrial products and can provide a complete solution including touchscreen, driver board, and cables.

However, the larger screen size and higher brightness also bring a corresponding increase in power consumption. The estimated total power consumption of about 6.5W is much higher than the approximately 2.6W of the 10.4-inch solution. This is an important trade-off factor, and customers need to decide based on their equipment's energy budget and actual display effect requirements. If the application scenario does not have high requirements for display details, the SVGA resolution on a 12.1-inch screen can still provide acceptable clarity.

Table 3: Detailed Specifications – BOE BA121S01-200 & AMT9542 Resistive Touchscreen

| Parameter | BOE BA121S01-200 Specification | AMT9542 Specification |

|---|---|---|

| Size | 12.1 inch | 12.1 inch |

| Resolution | 800 x 600 (SVGA) | Adapts to 800 x 600 |

| Brightness | 400 cd/m² (Typ.) | - |

| Contrast Ratio | 800:1 (Typ.) | - |

| Viewing Angle (L/R/U/D) | 80/80/65/75 (CR≥10, Typ.) | - |

| Operating Temperature | -20 ~ 70°C | -20 ~ 70°C |

| Storage Temperature | -30 ~ 80°C | -40 ~ 80°C |

| Backlight Type/Lifespan | WLED / 30,000 hours (Min.) | - |

| Panel Logic Power Consumption | 0.40W (Typ.) / 0.45W (Max.) | - |

| Backlight Power Consumption | 6.0W - 6.12W (Typ.) | - |

| Total Power Consumption (Est.) | ~6.4W - 6.57W (Typ.) | - |

| Vibration Resistance (Panel) | Data to be confirmed | - |

| Touch Type | - | 4-wire Resistive |

| Touch Interface | - | USB, RS232 |

| Transmittance | - | ≥80% |

| Surface Hardness | Anti-Glare (AG) | 3H |

| Touch Points/Lifespan | - | Single-point / >1 million actuations |

| Signal Interface (Panel) | LVDS (1 ch, 6/8-bit), 20 pins | - |

| Supply Voltage (Panel) | 3.3V (Typ.) | - |

Note: The anti-vibration specification for the BA121S01-200 panel was not explicitly found in the current data. However, as an industrial-grade panel, it usually meets certain anti-vibration standards. For specific requirements, it is recommended to consult LEEHON Technology for confirmation.

This table provides key parameters for the 12.1-inch solution, facilitating comparison with the 10.4-inch solution and the AUO 12.1-inch competitor to be discussed later.

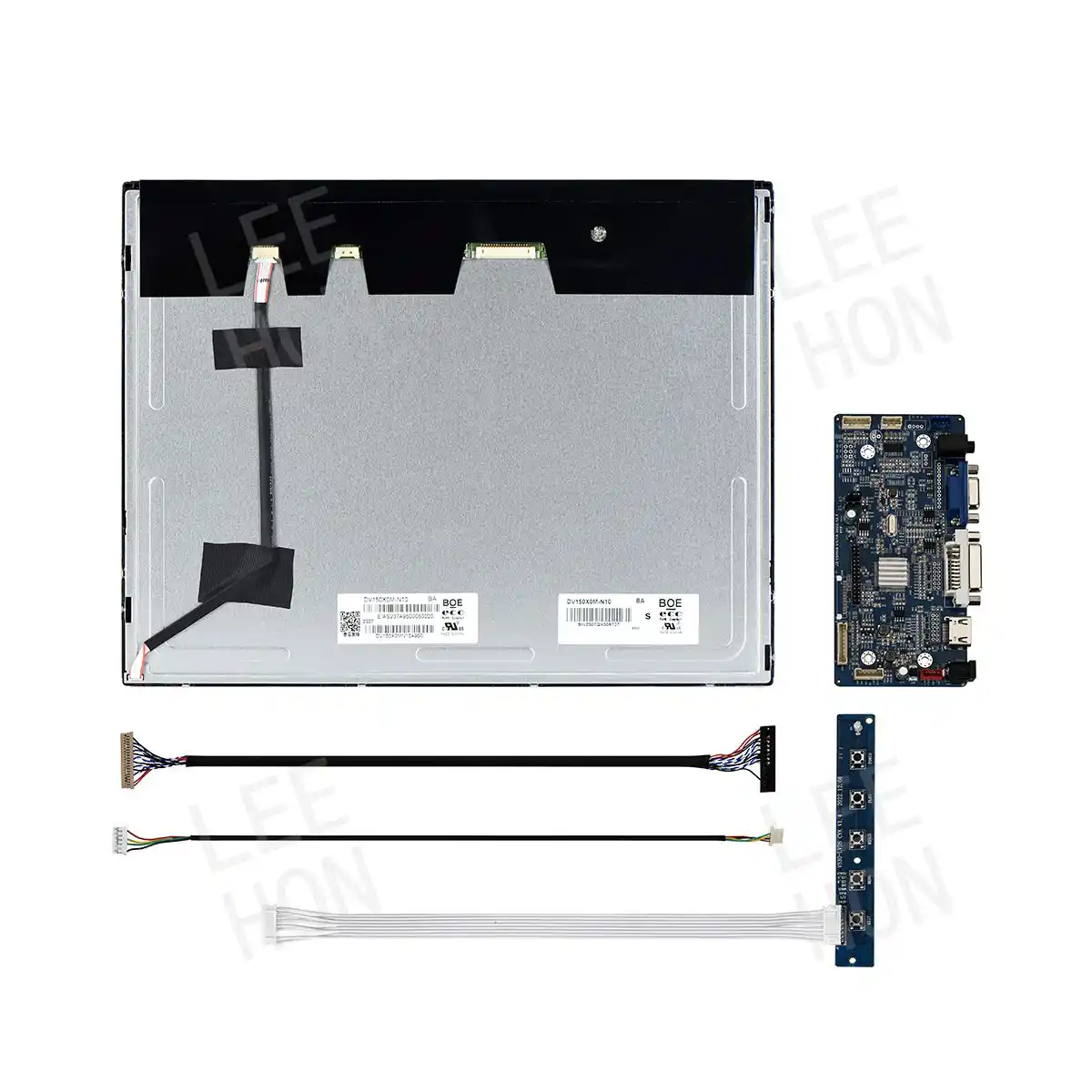

2.3. Solution Focus Three: BOE DV150X0M-N11 (15.0-inch) with AMT9102 Resistive Touchscreen

BOE DV150X0M-N11 LCD Display Panel

The BOE DV150X0M-N11 is a 15.0-inch XGA (1024x768) resolution high-performance TFT-LCD display module. It utilizes ADS (Advanced Super Dimension Switch) display technology, providing extremely wide symmetrical viewing angles (89/89/89/89), ensuring color and contrast consistency when viewed from different directions. The panel has a typical brightness of 350 cd/m², a high contrast ratio of 1000:1, and an operating temperature range of -20°C to +70°C. Its WLED backlight has a lifespan of up to 50,000 hours, significantly better than the previous two BOE models. The panel surface is treated with anti-glare (Haze 25%) and hard coating (3H), uses an LVDS interface, and has a 1.2G anti-vibration capability. In terms of power consumption, the panel logic circuit consumes about 0.8W to 1.3W, and the backlight consumes about 7.92W to 8.71W, making the total power consumption between 8.72W and 10.1W.

AMT9102 Resistive Touchscreen

The matching AMT9102 is a 15.0-inch (4:3 aspect ratio) 4-wire resistive touchscreen. Its standout feature is a high light transmittance of over 90%, which is excellent for a resistive screen, maximally preserving the brightness and color of the display panel. It has a surface hardness of 3H, an operating temperature range of -20°C to +70°C, and supports USB and RS232 interfaces. In terms of durability, the AMT9102 can withstand over 1 million touch operations.

Combined Advantages and Textile Machinery Application

The combination of BOE DV150X0M-N11 and AMT9102 constitutes the high-end large-size HMI solution among LEEHON Technology's recommended products. The 15-inch display area and XGA resolution provide ample space and fine image quality for complex textile machinery monitoring interfaces, capable of clearly displaying process flowcharts, multiple sets of data parameters, or high-definition images. The ultra-wide viewing angle brought by ADS technology is particularly important for scenarios in busy and spatially variable factory workshops where operators need to observe the screen from different angles, effectively avoiding information misreading due to viewing angle issues.

A backlight lifespan of up to 50,000 hours means lower maintenance frequency and longer trouble-free operation time, thereby reducing the equipment's total cost of ownership (TCO). This is an important consideration for industrial equipment pursuing long-term stable operation. The high transmittance characteristic of the AMT9102 touchscreen ensures that the loss of display brightness and color is minimized after adding the touch layer, maintaining an excellent visual experience.

This combined solution is suitable for textile dyeing and printing equipment with high requirements for HMI performance, display quality, and long-term reliability, such as advanced dyeing machine and printing machine control systems, or central monitoring platforms.

Table 4: Detailed Specifications – BOE DV150X0M-N11 & AMT9102 Resistive Touchscreen

| Parameter | BOE DV150X0M-N11 Specification | AMT9102 Specification |

|---|---|---|

| Size | 15.0 inch | 15.0 inch |

| Resolution | 1024 x 768 (XGA) | Adapts to 1024 x 768 |

| Display Technology | ADS, Normally Black, Transmissive | - |

| Brightness | 350 cd/m² (Typ.) | - |

| Contrast Ratio | 1000:1 (Typ.) | - |

| Viewing Angle (L/R/U/D) | 89/89/89/89 (CR≥10, Typ.) | - |

| Operating Temperature | -20 ~ 70°C | -20 ~ 70°C |

| Storage Temperature | -20 ~ 70°C | -40 ~ 80°C |

| Backlight Type/Lifespan | WLED / 50,000 hours (Min.) | - |

| Panel Logic Power Consumption | 0.8W (Typ.) / 1.3W (Max.) | - |

| Backlight Power Consumption | 7.92W (Typ.) / 8.71W (Max.) | - |

| Total Power Consumption | 8.72W (Typ.) / 10.1W (Max.) | - |

| Vibration Resistance (Panel) | 1.2G (11.76 m/s²) | - |

| Touch Type | - | 4-wire Resistive |

| Touch Interface | - | USB, RS232 |

| Transmittance | - | ≥90% |

| Surface Hardness | Anti-Glare (Haze 25%), Hard coating (3H) | 3H |

| Touch Points/Lifespan | - | Single-point / >1 million actuations |

| Signal Interface (Panel) | LVDS (1 ch, 8-bit), 20 pins | - |

| Supply Voltage (Panel) | 3.3V (Typ.) | - |

This table showcases the excellent performance parameters of the 15-inch solution, especially the ADS technology and long-life backlight. These data provide a basis for evaluating its suitability in high-end or complex HMI applications.

Chapter 3: Comparative Analysis: Revealing the Cost-Benefit Advantages of BOE Solutions

This chapter aims to clarify the cost-benefit advantages of the BOE display and AMT resistive touchscreen combination solutions recommended by LEEHON Technology, relative to specific AU Optronics (AUO) models, through direct comparison. The analysis will focus on key performance indicators most relevant to textile industry customers, including display quality, durability, operating range, power efficiency, and expected lifespan, combined with a comprehensive consideration of potential cost factors.

3.1. BOE BA104S01-300 (+AMT9509) vs. AUO G104STN01.0 – 10.4-inch Showdown

Specifications and Performance Comparison

| Feature | BOE BA104S01-300 (+AMT9509) | AUO G104STN01.0 | Advantage |

|---|---|---|---|

| Resolution | 800 x 600 (SVGA) | 800 x 600 (SVGA) | Same |

| Brightness (Typ.) | 350 cd/m² | 400 cd/m² | AUO (Slightly higher) |

| Contrast Ratio (Typ.) | 800:1 | 700:1 | BOE |

| Viewing Angle (L/R/U/D) | 80/80/65/75 | 80/80/60/70 | BOE (Slightly better up-angle) |

| Operating Temperature | -20 ~ 70°C | -30 ~ 80°C | AUO (Wider range) |

| Backlight Lifespan (Typ./Min.) | 30,000 hours | 50,000 hours(Some data 70K) | AUO (Significantly longer) |

| Total Power Consumption (Typ./Max.) | ~2.57W (Max.) | ~4.38W (Typ.) | BOE (Significantly lower) |

| Vibration Resistance | 1.5G (14.7 m/s²) | 1.5G (14.7 m/s²) | Same |

| Touch Solution | AMT9509 (4-wire Resistive) | Typically requires separate sourcing | BOE (LEEHON provides integrated solution) |

Performance Analysis and Cost-Benefit Considerations

As seen from the table, AUO G104STN01.0 has advantages in brightness, operating temperature range, and backlight lifespan. However, BOE BA104S01-300 performs better in contrast ratio (usually meaning better image sharpness and text readability) and, crucially, power consumption. The BOE solution's total power consumption is significantly lower than the AUO model, which means considerable energy cost savings in long-term operation, especially in factory environments with a large number of HMI devices.

The cost-benefit advantage of the BOE solution is mainly reflected in the balance between its lower initial procurement cost (this is a common market perception, specific details need confirmation with LEEHON Technology) and significant operating energy savings. Although AUO G104STN01.0 has a longer rated backlight lifespan (50,000 hours versus 30,000 hours), for textile machinery that does not operate 24/7, or for customers more sensitive to initial investment, the 30,000-hour backlight lifespan of BOE BA104S01-300 (equivalent to nearly 7 years of use if operated 12 hours a day) may be sufficient. In this case, its lower purchase price and power savings of approximately 1.8W per hour will make its total cost of ownership more attractive.

Furthermore, the integrated solution of BOE BA104S01-300 with AMT9509 resistive touchscreen provided by LEEHON Technology offers customers a proven, out-of-the-box HMI module, simplifying the selection and integration process.

3.2. BOE BA121S01-200 (+AMT9542) vs. AUO G121XN01 V0 – 12.1-inch Competition

Specifications and Performance Comparison

| Feature | BOE BA121S01-200 (+AMT9542) | AUO G121XN01 V0 | Advantage |

|---|---|---|---|

| Resolution | 800 x 600 (SVGA) | 1024 x 768 (XGA) | AUO (Significantly higher) |

| Brightness (Typ.) | 400 cd/m² | 500 cd/m² | AUO |

| Contrast Ratio (Typ.) | 800:1 | 700:1 | BOE |

| Viewing Angle (L/R/U/D) | 80/80/65/75 | 80/80/80/80 (or 80/80/70/70) | AUO (Usually wider or better symmetry) |

| Operating Temperature | -20 ~ 70°C | -30 ~ 85°C | AUO (Wider range) |

| Backlight Lifespan (Typ./Min.) | 30,000 hours | 50,000 hours | AUO (Significantly longer) |

| Total Power Consumption (Typ.) | ~6.57W (Est.) | ~9.15W(or 9.2W^52^) | BOE (Significantly lower) |

| Vibration Resistance | Data to be confirmed | 1.5G (14.7 m/s²) | AUO (Clear data available) |

| Touch Solution | AMT9542 (4-wire Resistive) | Typically requires separate sourcing | BOE (LEEHON provides integrated solution) |

Performance Analysis and Cost-Benefit Considerations

At the 12.1-inch level, AUO G121XN01 V0 outperforms BOE BA121S01-200 in several key specifications (resolution, brightness, operating temperature range, backlight lifespan). The main advantages of the BOE model are its higher contrast ratio and significantly lower power consumption.

Therefore, the cost-benefit argument for BOE BA121S01-200 largely depends on the highly competitive procurement price that LEEHON Technology can offer. If the customer's application scenario does not have a strict requirement for XGA resolution, SVGA (800x600) on a 12.1-inch screen may be sufficiently clear for many textile machinery control interfaces. Under this "good enough" principle, the low cost and low power consumption characteristics of the BOE solution will highlight its value. Not all applications require the highest specification parameters; if the HMI task is mainly to display relatively simple information and control buttons, the higher pixels and brightness of the AUO model may not bring additional value commensurate with its cost. LEEHON Technology's professional team can assist customers in evaluating their actual needs to select the most suitable and economical solution.

3.3. Unique Advantages of BOE DV150X0M-N11 (+AMT9102) in Large-Size Applications

Since the user query did not specify a 15-inch AUO competitor model, this section will focus on elaborating the outstanding advantages of the BOE DV150X0M-N11 and AMT9102 combination as a standalone high-end solution for textile applications requiring larger HMI interfaces.

The core features of BOE DV150X0M-N11 include a 15.0-inch XGA resolution, advanced ADS display technology (providing ultra-wide symmetrical viewing angles of 89/89/89/89), a high contrast ratio of 1000:1, a backlight lifespan of up to 50,000 hours, anti-glare surface treatment, and 1.2G anti-vibration capability. The matching AMT9102 resistive touchscreen boasts a light transmittance of over 90% and a touch lifespan of over one million actuations.

These features collectively bring significant operational advantages to complex textile machinery control interfaces:

- Larger Screen Space: The 15-inch display area allows for more comprehensive data display and more relaxed control layout.

- XGA Resolution: Ensures excellent clarity when displaying fine process flowcharts or multiple data sets.

- ADS Ultra-Wide Viewing Angle: In busy factory workshops with variable operating positions, operators can obtain consistent and clear images regardless of the viewing angle, which is crucial for avoiding misoperations.

- Long Backlight Lifespan: A 50,000-hour backlight lifespan significantly reduces maintenance requirements and total cost of ownership (TCO).

- High Transmittance Touchscreen: The excellent light transmittance of AMT9102 minimizes the impact of the touch layer on display brightness and color, ensuring a superior visual experience.

- Reasonable Power Consumption: Relative to its size and performance, the typical total power consumption of 8.72W is controlled within a reasonable range, helping to enhance the cost-effectiveness of the overall solution.

The combination of BOE DV150X0M-N11 and AMT9102 is designed for application scenarios requiring large-size, high-quality displays for complex equipment monitoring and refined control. The synergistic effect of its ADS panel technology and high-transmittance touchscreen ensures optimal visual effects, while the long-life backlight guarantees long-term economy.

Table 5: Key Cost-Benefit Advantages Summary – LEEHON Technology Recommended BOE + AMT Solutions

| Model Combination | Key Differentiators vs. Competitors (or Market Norm) | Main Benefits for Textile Industry | Cost-Benefit Advantage Points |

|---|---|---|---|

| BOE BA104S01-300 + AMT9509 (10.4”) | Lower power consumption (approx. 40% saving), higher contrast ratio; shorter backlight lifespan, slightly narrower operating temp. range | Significantly reduces running energy consumption, improves image clarity; integrated AMT touchscreen provides reliable glove operation and industrial-grade durability | Lower initial procurement cost (expected) and significant electricity savings may offset replacement costs from shorter backlight lifespan, especially for non-24/7 equipment |

| BOE BA121S01-200 + AMT9542 (12.1”) | SVGA resolution (competitor XGA), slightly lower brightness, shorter backlight lifespan; but significantly lower power consumption (approx. 28% saving) | Provides larger display area while maintaining low operating costs; an extremely price-competitive option if XGA is not essential | If SVGA resolution meets application needs, offers excellent value proposition through substantially lower procurement cost (expected) and significant energy savings |

| BOE DV150X0M-N11 + AMT9102 (15.0”) | XGA resolution, ADS ultra-wide viewing angle, 50,000-hour long-life backlight, AMT touchscreen transmittance ≥90% | Delivers superior visual experience and operational convenience, suitable for complex monitoring interfaces; significantly extends maintenance cycles, lowering long-term ownership cost | Provides excellent long-term ROI for high-end applications due to outstanding optical performance, long-life design, and high-quality touch integration |

Chapter 4: Why Choose Hangzhou LEEHON Technology and BOE as Your Ideal Partners for Your Textile Business

Choosing the right Human-Machine Interface (HMI) supplier is not just about purchasing a component; it's about selecting a partner who can provide continuous value and support. Hangzhou LEEHON Technology Co.,Ltd. (LEEHON Technology), with its profound industry experience, comprehensive technical support, and close cooperation with leading manufacturers like BOE, is committed to providing textile industry customers with optimized display solutions.

4.1. LEEHON Technology's Advantages: Expertise, Comprehensive Support, and Customization Services

Since its establishment in 2009, Hangzhou LEEHON Technology has accumulated over a decade of professional experience in the industrial display field and has grown to become a major agent for several well-known brands, including BOE, in mainland China. This enables LEEHON Technology not only to offer a wide range of product choices but also to provide professional selection advice based on a deep understanding of the market and technology.

One of LEEHON Technology's core strengths lies in its ability to provide "total display solutions." This includes TFT LCD display screens, matching resistive or capacitive touchscreens, high-performance controller boards, necessary connecting cables, and even open-frame complete machines. This one-stop service model greatly simplifies the R&D and procurement processes for textile machinery manufacturers, shortens product time-to-market, and reduces system integration risks. For OEM manufacturers who wish to focus on their core machinery manufacturing capabilities, LEEHON Technology is undoubtedly an ideal partner capable of shouldering the HMI subsystem integration responsibilities.

Furthermore, LEEHON Technology offers strong technical support and flexible customization services. Whether it's "sunlight readable" high-brightness display solutions for outdoor high-light environments, heating solutions for adapting to extremely low-temperature environments, or the integration of touchscreens with specific sizes, interfaces, or functions, LEEHON Technology can adjust and optimize according to the customer's specific needs. The company's physical operation center in Hangzhou, China ^54^, also provides local textile industry customers with convenient communication channels and timely technical responses, which is crucial for handling complex technical issues and ensuring smooth project progress.

4.2. BOE's Quality Commitment and Innovation Strength in the Industrial Display Field

As a world-leading provider of semiconductor display products and solutions, BOE has earned widespread recognition in the industrial display field for its excellent quality, continuous technological innovation, and stable supply capabilities. BOE focuses on designing and manufacturing display screens for harsh industrial environments, and its products are widely used in various applications requiring high reliability and outstanding display performance.

The ADS (Advanced Super Dimension Switch) technology used in the BOE DV150X0M-N11 model highlighted in this report, and its backlight lifespan of up to 50,000 hours, are manifestations of BOE's technical strength. ADS technology provides IPS-like wide viewing angles and accurate color reproduction, while the long-life backlight ensures the durability of the display screen under long hours of continuous operation. These features are of extremely high value to industrial users who require long-term stable operation of equipment and are sensitive to maintenance costs.

BOE's leading position in the global display market also signifies its substantial investment in R&D and strict production quality control systems. Choosing BOE products means choosing a brand that is guaranteed in terms of technological advancement and product reliability. This is an important consideration for textile machinery manufacturers who need to ensure the long-term competitiveness of their equipment.

4.3. Long-Term Reliability and Supply Chain Stability from Partnering with LEEHON Technology and BOE

Industrial machinery and equipment typically have long service cycles, so the long-term stable supply of core components (such as HMIs) is crucial. The premature end-of-life (EOL) of any key component can bring expensive redesign costs or urgent stocking pressure to equipment manufacturers.

Hangzhou LEEHON Technology, as an authorized agent for renowned manufacturers like BOE, has established stable cooperative relationships with these original factories, providing customers with more reliable supply chain assurance. The BOE models recommended in this report, such as BA104S01-300, BA121S01-200, and DV150X0M-N11, are currently in "In Production" status, ensuring supply capability for the present and the foreseeable future.

By partnering with LEEHON Technology to procure BOE display products, textile industry customers not only receive high-quality HMI components but also benefit from a relatively stable supply chain system, thereby effectively reducing operational risks arising from component supply disruptions. This long-term reliability is a highly valued aspect for industrial customers when selecting suppliers.

Chapter 5: Conclusion: Selecting the Optimal HMI for Textile Dyeing and Printing Operations to Enhance Productivity and Reliability

5.1. Summary of Key Findings and Recommendations

The production environment in the textile dyeing and printing industry presents multifaceted and severe challenges for Human-Machine Interface (HMI) systems. These include wide temperature and humidity ranges, ingress of dust and liquids, chemical corrosion, mechanical vibration, and requirements for operational convenience (such as glove operation). Selecting the appropriate HMI solution is crucial for ensuring stable equipment operation, improving operational efficiency, and guaranteeing product quality.

This report, through a detailed analysis and comparison of three core BOE LCD display screens (BA104S01-300, BA121S01-200, DV150X0M-N11) combined with AMT high-quality resistive touchscreens, reveals their cost-benefit advantages in textile dyeing and printing applications:

- BOE BA104S01-300 (10.4-inch) + AMT9509: This combination, with its excellent power consumption control and good contrast ratio, is a highly cost-effective choice for standard application scenarios. It is particularly suitable for customers with high requirements for initial investment and long-term operational energy consumption.

- BOE BA121S01-200 (12.1-inch) + AMT9542: For applications requiring a larger display area but still with SVGA resolution requirements, this solution offers good value for money while maintaining low power consumption. If XGA resolution is not essential, this is an economical upgrade option worth considering.

- BOE DV150X0M-N11 (15.0-inch) + AMT9102: As a high-end 15-inch XGA solution, it provides excellent performance and a lower total cost of ownership (TCO) for complex HMI needs, thanks to its superior ADS wide viewing angle technology, a backlight lifespan of up to 50,000 hours, and a high-transmittance AMT resistive touchscreen.

These BOE and AMT combination solutions, recommended by Hangzhou LEEHON Technology, are optimized for the specific needs of the textile industry, performing excellently in terms of durability, reliability, and operational practicality. Importantly, this report does not offer a "one-size-fits-all" answer but provides tiered recommendations, enabling customers to make the most informed choices based on their specific performance requirements, application scenarios, and budget constraints. This once again validates LEEHON Technology's role as a professional display solutions consultant.

5.2. Call to Action: Partner with Hangzhou LEEHON Technology for a New Future in HMI Solutions

Choosing the best Human-Machine Interface solution for your textile dyeing and printing machinery is a key step towards enhancing equipment performance, optimizing production processes, and strengthening market competitiveness. Hangzhou LEEHON Technology Co.,Ltd., with its profound expertise in the industrial display sector, close partnerships with leading manufacturers like BOE, and its capability to provide comprehensive technical support and customized services, is your trustworthy partner.

We cordially invite you to contact LEEHON Technology's professional team for more detailed product information, specific quotations, and to jointly explore HMI solutions that meet your unique needs.

Contact Information:

- Company Name: Hangzhou LEEHON Technology Co.,Ltd.

- Address: Rm B-4118, Golden Bull Building, No.8 Gaoshun Road Xixi Software Park, Yuhang District, Hangzhou city, Zhejiang, China

- Telephone: 0086-15906639973

- Email: info@leehon.com

- Websites:https://www.lcd-panel.cn, https://www.lhlcdpanel.com

By adopting advanced display technology, let us jointly propel your textile business towards higher production efficiency and operational reliability.

Recommended Articles

-

Optimizing Human-Machine Interf

2025-05-29 -

Hangzhou LEEHON Technology Reco

2025-05-28 -

Report: Handheld Drone Ground C

2025-05-27 -

Report Title: Display Screen Se

2025-05-27 -

Downhole Operation Equipment Sc

2025-05-26 -

Optimizing Rail Transit Cockpit

2025-05-26 -

LCD Screen Selection and Soluti

2025-05-23 -

Optimizing Industrial Teach Pen

2025-05-23 -

How to Select a Screen for Ultr

2025-05-22 -

Optimal Infrared Display Select

2025-05-21 -

Machine Tool Control Panel Scre

2025-05-21 -

LCD Screen Selection Strategy a

2025-05-20 -

G057VN01 V2 LCD Panel for Cutti

2025-05-15 -

Why the Textile Industry Choos

2025-05-09 -

Outstanding Application and Adv

2025-04-28 -

Paperless Meeting System LCD Sc

2025-04-15 -

LEEHON's Comprehensive Screen S

2024-11-29 -

LEEHON's Comprehensive Screen S

2024-11-29 -

G104XVN01.0 as a Solution for W

2024-10-09 -

G190ETN01.4 and G150XTN06.0 as

2024-10-09